How cadis® can support last mile delivery

Customers, very often pharmacies, can order several times in one day and always expect prompt delivery. This requires permanent route optimization, as the order is often received just before the vehicle is loaded. Fortunately, cadis® Route Planner supports the dispatcher with an adjustable set of rules for route optimization and provides online track & trace for all shipments down to individual package level. Starting with loading at the depot in the morning, deliveries and collections on the route through to unloading at the end of the day, cadis® makes all information available to dispatchers in real time. Temperature-sensitive product groups are marked in the system and can be handled separately.

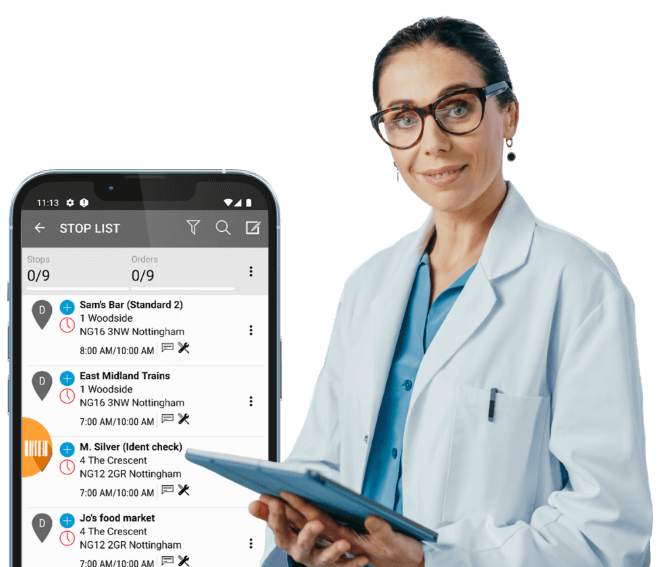

Where cadis® will help drivers on the road

With the intuitive cadis® APP, drivers are supported when loading at the depot and processing their tours. At each tour stop, the drivers receive all the information they need via the app. The consignee can confirm receipt of the consignment and the exchange of the load carriers with a digital signature. Any damage is documented on site using the photo function and can be viewed in the shipment history.

Can’t find a feature you are looking for?

cadis® temperature monitoring and management

For temperature-sensitive goods, the required temperature range must be reliably monitored. The cadis® Temperature Monitoring feature automates the temperature documentation process, thus stopping a manual and time consuming task. As a result, you will be able to provide customers with their temperature reports quickly, in an easy-to-digest format with no gaps or errors. The manual provision of individual temperature curves is no longer necessary and the important Proof of Storing Conditions documentation is immediately available.

To minimize the risk of temperature damage, the temperature of the cargo chambers is measured at short intervals via a connected telematics service provider and immediately displayed in cadis® in case of undesirable deviations.

What’s more, the storage areas in any cross-docking halls are known in cadis® and can be assigned to temperature ranges. This ensures that goods are directed to the right place and stored correctly according to the temperature specifications for the time until loading.

cadis® Master Pallet for grouping shipments

If goods are sent over long distances, several depots are involved. To avoid having to scan all packages individually for each logistics process, cadis® can use its Master Pallet function to group them on the depot or consignee level. When the last depot is reached the master pallet can be ungrouped. In case of a master pallet that is consolidated for a consignee, it can even be used all the way to the delivery, thus saving a lot of time and increasing productivity.